Zone Refining in India

Zone Refining in India

- Zone optimizing denotes the way of draining a crystal in which a lean area of the crystal leaves melting. This’molten zone’ is moved from the other side of the crystal clear.

- The beams from the alloy have been thrown in the forward’s border from the bronchial zone and continue throughout the cube of alloy, leaving the solidified pure part beneath. The Induction Zone Refining strategy entails cutting down a narrow corner of the very long ingot of this substance to be processed.

- This particular zone is subsequently moved by shifting the semi Coil little by little across the duration of this ingot in 1 route. The following procedure is replicated a number of times before essential payoff amount has been arrived at. Inside this technique gap amongst solubility of impurities at the solid stages is utilized to curb impurities in the ending element of their ingots.

- Engineered heating is perfect for this technique as warmth is speedily generated in the content forming a sharp slim zone. In addition, the temperatures which may be achieved are substantially more compared to the one’s conventional heaters. Since they proceed throughout the cube of alloy, the impurities from the alloy have been focused at the softening and therefore are glued to an ending of their metallic block.

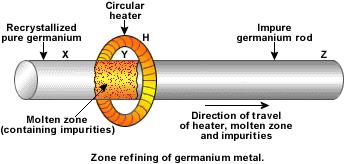

- A good example of this course of action is offered beneath. From the zone optimizing procedure, around the portable heater is repaired by an end of this metallic pole that’s composed of the impure alloy. The curved portable heater has been transferred slowly through the metallic pole. The aluminum beams melt the momentary location of the grills. The flow comprising the impurities goes forward together side all the heater throughout the conclusion of this metallic pole. The metal is made to pierce whilst the heater goes across the pole. Whilst the heater goes ahead, the focus of these impurities at the meltdown increases.

- That really is only because the impurities tend to be somewhat more soluble inside their corresponding melting condition. At length, the impurities have been collected at an end of their metallic pole. The method explained above is replicated often at an identical route. At the close of the pole where the impurities have accumulated inside is take away, leaving supporting the metal. An example of the procedure is furnished beneath.

Zone Refining in India,Zone Refining in India,Zone Refining in India,Zone Refining in India,Zone Refining in India

Leave a Reply

Want to join the discussion?Feel free to contribute!