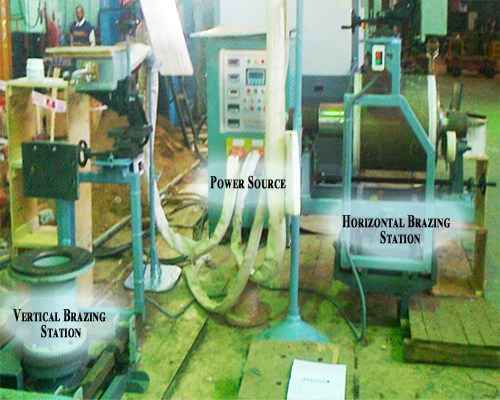

Induction Brazing Plant /Machine

Induction Heating for Soldering

Induction brazing is a process in which two or more materials are joined together by a filler metal that has a lower melting point than the base materials using induction heating.

VEL Induction Heater (Type VEL/BR series) is specially designed for Induction Brazing

| TYPE | VEL/BR20 | VEL/BR50 | VEL/BR80 | VEL/BR120 | VEL/BR200 | VEL/BR320 |

| Input feeder rating | 40 A | 100 A | 160 A | 250 A | 400 A | 600 A |

| Output power | 20 kW | 50 kW | 80 kW | 120 kW | 200 kW | 320 kW |

| Output frequency | 10-40 kHz | 10-40 kHz | 10-40 kHz | 10-40 kHz | 10-40 kHz | 10-40 kHz |

| Output voltage | 0-400 V | 0-400 V | 0-400 V | 0-400 V | 0-400 V | 0-400 V |

| Max output current | 800 A | 2000 A | 3200 A | 4800 A | 8000 A | 12000 A |

| Incoming voltage | 3phase, 415V, 50Hz, 4 wire | |||||

| Inverter | IGBT based Inverter | |||||

| Converter | Thyristor based Full Bridge Rectifier | |||||

| Output transformer | Compact design with flexible water cooled cable | |||||

| Type of cooling | Forced water cooling by Heat Exchanger & Cooling Tower of Power Devices, Capacitor, Chokes, Induction Coil, etc | |||||

Typical Induction Brazing Applications

| Brazing Carbide Tool | |

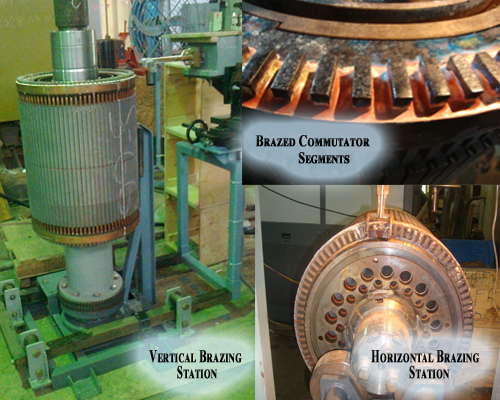

| Brazing of end winding lower and upper bar connection of stator of turbo generator. | |

| Brazing of Rotor Segments of Traction Motors of Indian Railways. | |

| Brazing Steel-Steel Parts | |

| Brazing Stainless Steel Orthodontic Parts | |

| Brazing Hydraulic Hose Assemblies and Manifolds | |

| Brazing Metering Plates to Turbine Blades With Nickel | |

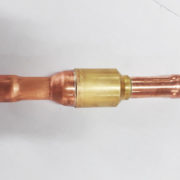

| Brazing Copper Tube Assemblies | |

| Brazing Stainless Steel to Brass | |

| Brazing Stainless Steel to Titanium | |

| Brazing Copper tube to brass fittings | |

| Brazing Brass-Brass parts | |

| Brazing of Heat Exchanger Parts | |